Innovative clean energy solutions to address carbon dioxide and hydrogen challenges

A multipronged strategy for hydrogen production as well as carbon capture, storage and utilization is set to provide sustainable energy solutions.

Sustainable energy sources are critical for both improving quality of life and fostering economic growth. However, fossil fuels dominate global energy production, causing substantial carbon dioxide and greenhouse gas emissions that harm the environment. Solutions to this fossil fuel dependency require a holistic approach encompassing economic, security and environmental considerations.

To address these challenges, Khalifa University has adopted a multipronged strategy encompassing carbon capture and hydrogen production. Carbon capture involves collecting produced carbon dioxide before its release into the atmosphere and either storing it in geologic formations or transforming it into useful products or materials. Developing the use of hydrogen, an energy vector that can be derived from low-carbon sources and serve as a clean fuel or feedstock, is equally important.

However, high costs and inadequate infrastructure have so far prevented these technologies from reaching their full potential. Now, thanks to cutting-edge research and innovation at KU’s Research and Innovation Center on CO2 and H2 (RICH), these issues are being addressed.

A mission to decarbonize

Under the directorship of Lourdes Vega, Khalifa University established RICH in 2019 to catalyze the United Arab Emirate’s energy transition away from fossil fuels. “We saw the opportunity to create this unique center after the Petroleum Institute, Masdar Institute, and Khalifa University of Science of Technology and Research merged into Khalifa University in 2017, bringing together experts in the fields of CO2 and hydrogen from the three institutions,” Vega says. The center is expected to generate knowledge and applications in the fields of CO2, hydrogen and clean energy.

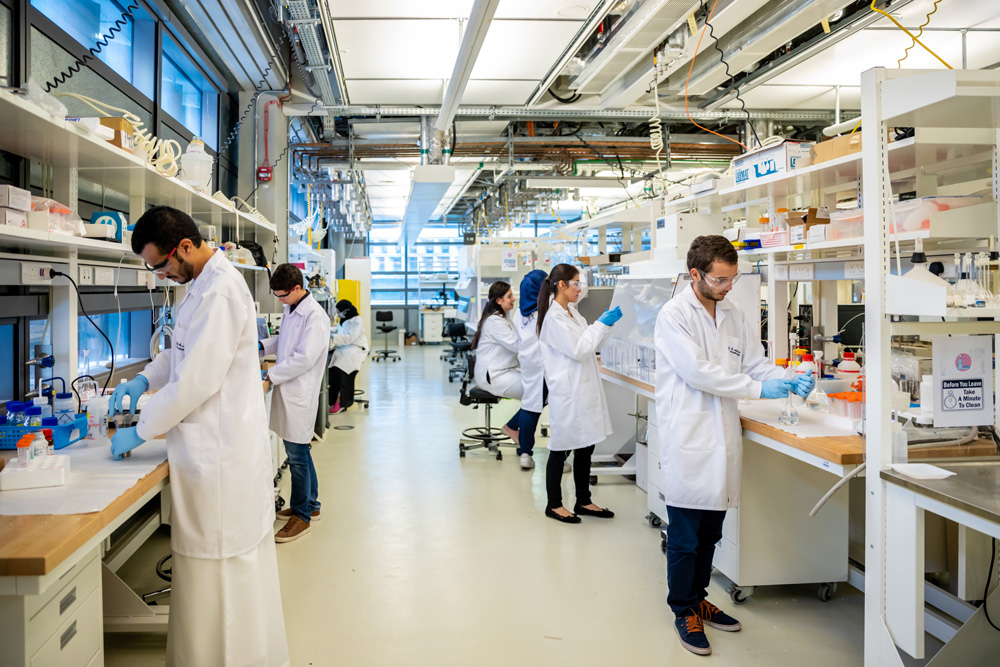

Research at RICH involves a multidisciplinary strategy combining modelling and experimental methods to develop novel materials and technologies for carbon capture and use, as well as hydrogen production, storage and distribution. It covers all areas ranging from materials chemistry, sustainable fuels, membranes, process modelling and optimization, biochemistry to fuel cells and life cycle assessment.

“Fundamental science is key for decarbonization and sustainability because [that’s how we make] technological breakthroughs, but we also need to put our determination and imagination into finding the best ways to apply it, so that the planet and society benefit from this knowledge. Hence, anyone can be part of the game,” explains Vega, who believes in leading by example.

The big picture

At RICH, engineer Ahmed Al Hajaj focuses on promoting and expediting the advancement of decarbonization technologies. He has devised an integrative approach to design high-performance carbon capture materials. His team seamlessly blends experiments, which generate vital data and material insights, with molecular simulations and process models.

This holistic approach provides the means to tailor material design and development stages based on an understanding of underlying physical phenomena. The approach also fast-tracks the maturation of novel materials and processes, he explains, allowing researchers to identify trade-offs associated with materials, and overcome issues that previously hindered large-scale technologies, including ill-fated commercial-scale carbon capture and sequestration projects.

Toward optimal carbon capture

Researchers at RICH have explored various innovative approaches to generate materials with enhanced carbon capture efficiency. They have modified the surface of graphene oxide—a high-surface-area derivative of the single-layered carbon-based material graphene that can adsorb gas molecules—using UV light. The resulting graphene oxide foam captured 30 times more carbon dioxide and presented seven times greater capacity under certain conditions compared with the unmodified material.

They have also produced activated carbon-based materials from nontraditional sources, such as waste from date seeds and developed hybrid materials, such as graphene oxide and highly ordered porous compounds called metal organic frameworks. These hybrids exhibit higher capture efficiency than their individual precursors.

Another approach conceived by Ludovic Dumée, an expert in molecular separation and selective resource recovery, focuses on extracting carbon dioxide present at low concentration in air and sea water. While challenging, this approach could help reduce emissions and generate CO2 on demand.

Dumée’s team is working on reducing the energy footprint of technologies involved in extracting carbon from dilute streams and, in this case, engineering scalable nanostructured materials that are more selective and easier to regenerate.

Aligning with global players

One of RICH’s main goals is to promote knowledge exchange, technology transfer and awareness of carbon and hydrogen-related technologies globally, fostering collaboration with industry and contributing to a sustainable energy future.

To enhance the center’s visibility, members organize events and participate in international conferences, such as the 15th International Conference on Greenhouse Gas Control Technologies, the 13th Asia-Pacific Conference on Combustion, and the 16th International Conference on Properties and Phase Equilibria for Process and Product Design.

“Faculty members at RICH are actively looking for collaborations from academia and industry, as this is part of our DNA, and the only way to be at the forefront in our areas of expertise,” Vega says.

Since the inception of the center, members have established academic connections around the world, with whom they exchange students and visitors, co-advise graduate students, and publish. They also closely collaborate with national and international companies, agencies and the government.

Emirates Steel Arkan and the cement company Al Jazeera Factory is working with RICH on a project that involves reacting carbon dioxide with waste from the steel factory to produce lightweight, precast, foam concrete building materials suitable for manufacturing block-like masonry units.

Another strategic collaboration with the energy group Advanced Turbine Development/Creative Power Solutions focuses on hydrogen based sustainable fuels for combustion. The partnership, managed by Dimitrios Kyritsis who oversees research on hydrogen transportation and utilization, has led to the creation of a high-pressure combustion research facility.

Provided by ATD/CPS and Atlas Electronik, the facility will make it possible to test flexible fuels derived from hydrogen, natural gas and ammonia-based hydrogen blends, and synthetic fuels developed in-house under industrial conditions.

“Our mission is to advance clean technologies as much as we can, and we are eager to put our efforts in this direction with as many partners as possible,” Vega says.