Delving into nanomaterials

Rashid K. Abu Al-Rub talks about his aim to revolutionise the application of nanomaterials by combining 2D materials and 3D printing

Exploring the mantra “smaller is stronger”, Rashid K. Abu Al-Rub has delved into the study of nanomaterials since gaining his PhD. As Professor of Mechanical Engineering and the Director of the Advanced Digital & Additive Manufacturing Center (ADAM) at Khalifa University, Abu Al-Rub’s focus lies in combining 2D materials and 3D printing, with the aim of enhancing the aerospace, defense and automotive sectors.

What inspires you?

I have always been captivated by the realm of nanotechnology. At the nanoscale, materials exhibit properties that are absent or limited at the macroscale emerge at the nanoscale. For example, several nanomaterials exhibit significantly greater strength compared to their bulkier counterparts. The classical examples are graphite and graphene: graphite, a brittle material that allows you to write with a pencil, stands in contrast to graphene, which consists of a single layer of carbon atoms and is one of the strongest materials in the world.

How would you sum up your research interest and expertise?

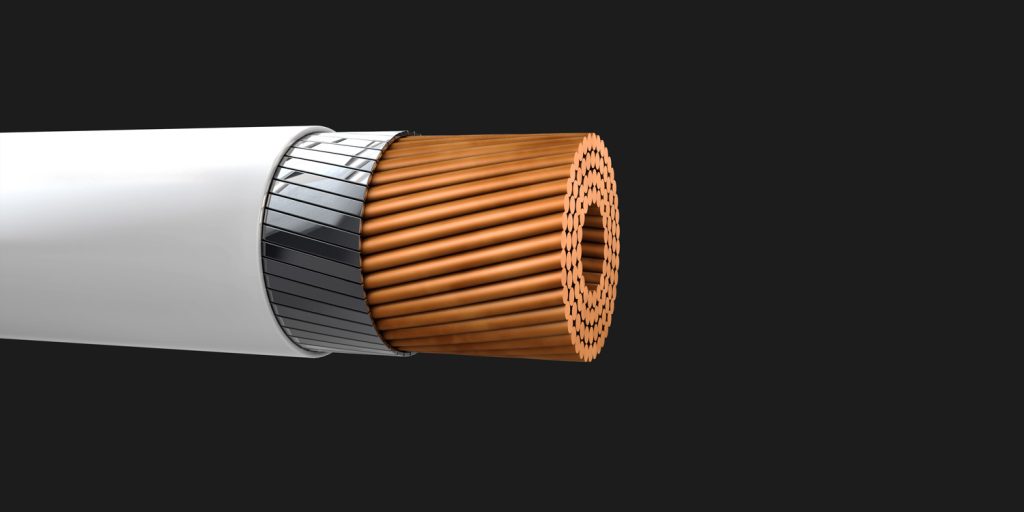

My research journey began with exploring ways to enhance the strength of concrete and polymers by mixing them with innovative nanomaterials. I began working with carbon nanotubes during my tenure at Texas A&M University in the United States, and then gradually turned to graphene.

Currently, I specialize in digital design and 3D printing, a form of additive manufacturing where 3D objects are created by adding material layer by layer.

I have also embarked on integrating graphene and other 2D materials, such as MXenes, into very complicated, lightweight 3D-printed objects. The term “MXene” is derived from their structure, where “M” represents a transition metal and “X” is carbon and/or nitrogen. These materials show interesting electronic and mechanical properties.

My research group achieved the first fabrication of very porous 3D-printed materials made of graphene and MXenes. Over the past eight years, we have become experts in producing 3D micro-architected materials and characterizing their mechanical and physical properties.

Do you envision the applications of these materials, especially in the aeronautics sector?

There are several possible applications. For instance, these special materials with graphene and MXenes can be designed to dissipate heat generated by electronic devices, preventing overheating. Their large surface area and excellent electrical conductivity make them ideal also as catalytic substrates and electrodes for energy storage devices.

In the aerospace industry, composites enhanced with 2D materials can add strength and special properties, such as self-sensing and self-healing. Imagine ‘smart materials’ that trigger an alarm when they sense damage.

Additionally, 2D materials can revolutionize electromagnetic shielding and absorption in defence-sector aircraft. For example, their use could prevent interception or jamming of the aircraft’s own emissions by adversaries.

Graphene and other 2D materials also excel in thermal conductivity and can act as efficient thermal barriers. They dissipate heat away from the ignition source, preventing the rapid spread of fire. Graphene can achieve these results with significantly lower concentrations compared to conventional fillers, such as carbon black.

What was the key take away for you from the recent UAE-EU symposium on 2D materials?

As well as presenting my group’s results , and attended presentations from different industries that showcased a multitude of successful applications for 2D materials, along with the challenges faced. I gained valuable insights and felt intrigued by companies that have achieved remarkable success with 2D materials. As a result, I’m initiating discussions with these companies to explore potential collaborations.

What advice would you give to aspiring PhD students with an interest in 2D materials?

The world of 2D materials is vast and continuously expanding. I would encourage aspiring PhD students to focus on a single application and identify the most promising 2D material for that application.

References

- Ashraf, J., Fu, J., Liao, K., Chan, V., Abu Al-Rub, R.K. “Scalable synthesis, characterization and testing of 3D architected gyroid graphene lattices from additively manufactured templates,” Journal of Micromechanics and Molecular Physics, Vol. 6, No. 3, pp. 13-24, 2021. | Article

- Fu, J., Taher, S.E., Abu Al-Rub, R.K., Zhang, T., Chan, V., Liao, K., “Engineering 3D-architected Gyroid MXene scaffolds for ultrasensitive micromechanical sensing,” Advanced Engineering Materials, Vol. 24, No. 7, 2101388, pp. 1-13, 2022. | Article

- Ashraf, J., Taher, S., Lee, D.-W., Liao, K., Abu Al-Rub, R.K. “On the computational modeling, additive manufacturing, and testing of tube-networks TPMS-based graphene lattices and characterizing their multifunctional properties,” APL Materials, Vol. 10, 121107, pp. 1-18, 2022. | Article