Precision printing: Optical filters made to order

From high-tech lenses to smart contacts with night vision, Khalifa University researchers can 3D print tailor-made optical filters to transform everything from solar panels to wearable tech.

Imagine a world where crafting the perfect optical filter is as simple as pressing “print”. From traffic lights to specialized cameras, these filters are essential for a wide range of technologies. Researchers at Khalifa University have developed a powerful 3D-printing method that can produce bespoke optical filters to meet any need.

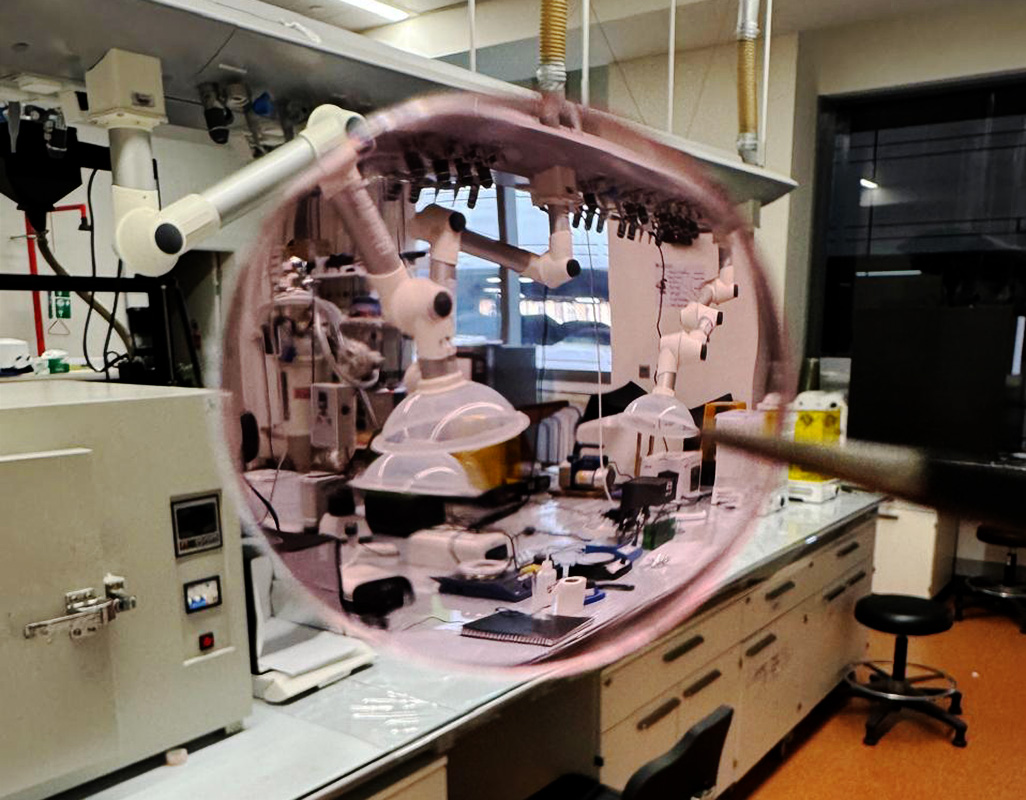

“Optical filters are used everywhere; in LED lighting, sunglasses, cameras and windows,” says Haider Butt from the Advanced Digital & Additive Manufacturing Group. “Similarly, when you want to use certain frequencies of light for optical communications, you use filters before the light enters optic fibers. Whenever we use microscopes and spectroscopes, we need filters ourselves to drive our research.”

“3D-printers are not known for their surface precision, but with our post-processing methods, we produce very smooth surfaces, allowing excellent transmission.”

Haider Butt

To unlock this level of flexibility, the team modified commercial 3D-printers and developed their own transparent resins and dyes. By adjusting the mix, they can now change the properties of the optical filters they produce; altering size, shape, thermal stability, strength. Most importantly, they can dictate the wavelengths of light that are absorbed and those that are transmitted.

“3D-printing is not a technique meant for large-scale production—it is more useful for customized, one-off designs,” says Butt. “For example, some patients need contact lenses with very particular shapes and filtering properties. The same goes for customized optical filters.”

The researchers have produced filters capable of selecting wavelengths across the entire spectrum, from blue to red, that can withstand stress, temperature and humidity without faltering. They are particularly proud of the quality of surface finish that they have achieved.

“The main reason optics manufacturers are good at what they do is because they produce a nice glossy surface finish, which prevents optical losses,” explains Butt. “3D-printers are not known for their surface precision, but with our post-processing methods, we produce very smooth surfaces, allowing excellent transmission.”

Automating production

Using their findings to train AI models, the team is now able to automate the production of optical filters based on a client’s specifications.

“Imagine a client comes to you saying they need a filter for a specific wavelength of red,” says Butt. “The AI model can inverse calculate the print parameters and combination of dyes we need.” The team has already demonstrated this method by replicating commercial filters based solely on optical graphs from the manufacturer’s website.

This work is already making waves in business. One exciting collaboration is with XPANCEO, a company whose main product line is smart contact lenses that give the wearer augmented reality features such as night vision and zoom.

“We are filing joint patents and co-authoring publications with them,” says Butt. “They are focused on making the electrical circuits that go into the lenses, and we are doing the 3D-printing.”

Reference

Ali, M., Elnemr, M., Ahmed, I., Samad, Y.A., Al-Rub, R.K.A., Butt, H. Development of functional optical filters via vat photopolymerization for advanced optical applications. Advanced Composites and Hybrid Materials 8:277 (2025) | Article