Engineering materials designed to think and protect

The future of air travel depends not only on fuel and engines, but also on what aircraft are made of. For three decades, Professor Wesley Cantwell has been honing his expertise in aeronautical engineering, designing lightweight, resilient and even ‘self-aware’ materials that are transforming the ways planes are built, fly and stay safe.

Before joining Khalifa University in 2012, Cantwell worked as a research scientist at the Ecole Polytechnique Fédérale de Lausanne, Switzerland. Later, he joined the University of Liverpool in the UK , where he led a team working on the impact behavior of lightweight materials and structures.

What prompted you to come to Khalifa University?

I was attracted by an exciting project, which promised state-of-the-art infrastructure to grow aerospace research and innovation and train professionals.

The aim was to establish the Aerospace Research and Innovation Center—now the Advanced Research and Innovation Center (ARIC)—as a hub for aerospace research. The center, designed to boost the aviation industry in the United Arab Emirates, was created as a partnership between state-owned investor Mubadala and KU, with support from local aerospace manufacturer Strata, which specializes in advanced composites and aerospace structures. Today, its scope has expanded to include advanced materials and applied technologies for digital, healthcare, and sustainability.

As the center’s founding director, I oversaw construction and equipment setup, recruiting personnel, and developing the research agenda.

What is your current role at the university?

I am no longer the director of ARIC. I am, however, a member of the Advanced Digital and Additive Manufacturing Group and my research team is investigating how to apply additive manufacturing to develop high-performance, energy-absorbing structures.

What are you exploring with your team?

Our research aligns with the university’s advanced materials and manufacturing strategy. We focus on composite materials, additive manufacturing, the impact response of structures, and smart materials.

“I was attracted by an exciting project, which promised state-of-the-art infrastructure to grow aerospace research and innovation and train professionals.”

Wesley Cantwell

One key area involves developing energy-absorbing structures designed to withstand impact and blast. We’ve engineered hierarchical honeycomb-like tube structures using carbon fiber-reinforced plastic to achieve exceptional blast resistance. We’ve used embedded composite tubes to strengthen and enhance the energy-absorption capabilities of lightweight structures, such as polymer foams and aluminum sandwich panels.

We are also exploring smart aircraft skins by integrating sensors into aircraft composite materials to create a self-aware structure that automatically detects minute damage and monitors its own structural health.

Another challenge that we work on is distortion in polymer-matrix composite components after manufacture, caused by residual stresses. To address this, we worked with Strata to develop a model to predict how much a component distorts during and after the manufacturing process.

What are your team’s most exciting and promising research findings?

One exciting finding involves energy-absorbing structures inspired by designs found in nature. By mimicking the microscopic features found in the stem of certain types of plant, we created honeycomb-like tubes with multi-level nesting. These bio-inspired structures greatly outperformed their conventional counterparts.

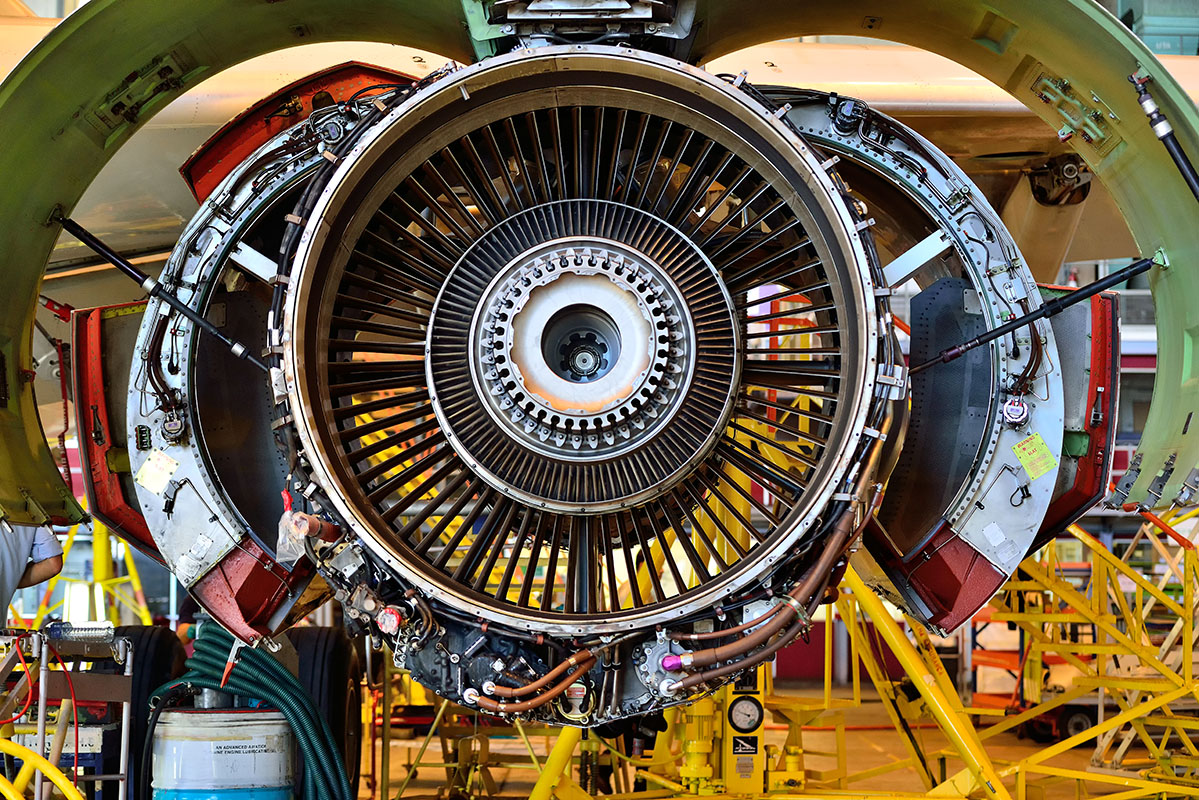

We’re also working with the aircraft engine maintenance, repair, and overhaul solution provider Sanad Aerotech to explore additive manufacturing techniques using metals to repair damaged aircraft components, such as jet engine compressor blades. Traditional repair methods are time-consuming and inefficient. This project aims to reduce the turnaround by rebuilding the component to its original shape using 3D printing.

How do partnerships drive your research focus—and what success stories stand out?

We have forged many project-specific collaborations with academia, industry and government locally and worldwide. For example, we are working on novel lightweight aerospace structures with Xi’an Jiaotong University, China, and Imperial College London, in the UK.

With Khalifa colleagues Rashid Abu Al Rub and Kin Liao, we have also initiated a project with the French aerospace company Dassault Aviation to conceive additively manufactured, noise-absorbing structures to tackle external aircraft noise and cabin acoustic insulation. The project is centered on lightweight, multifunctional materials and leverages 3D printing to create complex and optimized architectures.

What developments do you foresee for aerospace engineering?

The future of aerospace engineering will be defined by advancements in materials and manufacturing. This implies a greater focus on creating sustainable and multifunctional composite structures through methods such as 3D printing. Design approaches will shift from experimentation to multi-scale modeling, integrate new technologies, and improve recyclability.