Cleaning up industrial water with MXenes

A new, reusable material can be tuned to efficiently remove heavy metals from industry wastewater.

One of the most pressing environmental crises is unfolding in our waterways. Every day, industrial wastewater releases tons of hazardous chemicals, including heavy metals, directly into rivers and lakes around the world, poisoning water supplies. While current methods for removing these pollutants can be effective, they’re often costly and have limited lifetimes.

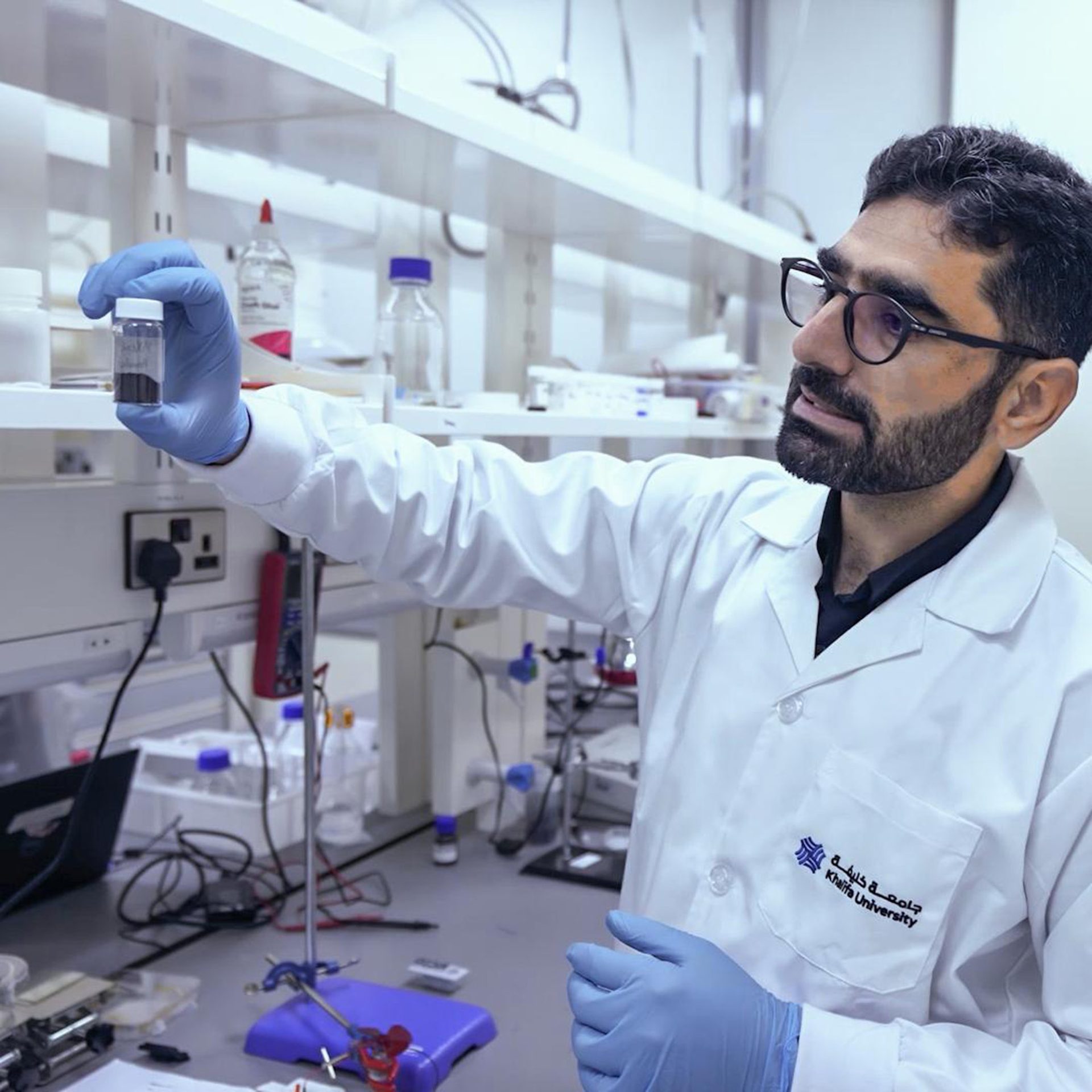

Now, a team of Khalifa University researchers, and co-workers in Pakistan, have found a new class of reusable adsorbents that can strip nickel and other dangerous pollutants from water, salvaging the valuable materials at the end of the process.

Nickel is often found in wastewater from industries such as electroplating smelting and battery-making. The team’s approach uses thin layers of metal called MXenes, which were discovered just over a decade ago.

“MXenes are fascinating materials,” says Faisal Shahzad, Senior Research Scientist at KU’s Chemical and Petroleum Engineering Department, who led the study. “By adding different functional chemicals to their surfaces, we can not only prevent the oxidation of MXenes, but also ‘tune’ the surfaces to adsorb heavy metal ions from wastewater.”

To enhance the material’s performance, Shahzad’s team added a chemical called called Trimethoxysilyl-ethylenediamine (tms-EDTA) to the surface. Their modified compound, EDTA@MXene, removed more than four times more nickel than basic MXene. Remarkably, even after five times cleaning and reused cycles, the EDTA@MXene retained over 80% of its efficiency.

“The EDTA acts to hold adjacent layers of MXene further apart, allowing more water to pass through the gaps and be treated,” says Shahzad. “We found that the nickel binds to EDTA@MXene both chemically and physically, but mostly physically, which is easier to reverse—it’s like prising open the fingers of the EDTA to release the nickel.”

While the reusability of EDTA@MXene, and the potential to retrieve most of the pure metals from it, make it a more environmentally sustainable solution for industrial use, the team acknowledges that they cannot yet compete financially with low-cost activated carbon filters. Still, they remain optimistic that with further development, their production of EDTA@MXene can soon be scaled up for commercial use.

“Our study focused on nickel, but our samples also showed excellent adsorption of cadmium, copper, lead and zinc,” says Shahzad. “We hope to develop methods for selective removal of all these specific metals from water.”

Shahzad is confident that the EDTA@MXene could even be re-used elsewhere when it becomes too full of nickel and is no longer suitable for wastewater treatment. “Nickel is an excellent catalyst, for example in water-splitting for hydrogen fuel production,” he says. “Why not give the nickel-adsorbed EDTA@MXene a new life?”

Reference

Kazmi, S.A.R., Husnain, S.M., Khan, A.R., Qureshi, T.M., Lemaoui, T., AlNashef, I.M., Arafat, H.A. and Shahzad, F., Removal of nickel ions from industrial wastewater using tms-EDTA-functionalized Ti3C2Tx: Experimental and statistical physics modeling. J. Haz. Mat., 490, 137667, 2025. | Article