Farming the future

At Khalifa University's Center for Autonomous Robot Systems, an ambitious partnership with agri-giant Silal is revolutionizing farming, using smart machines to tackle climate change and grow food in the desert.

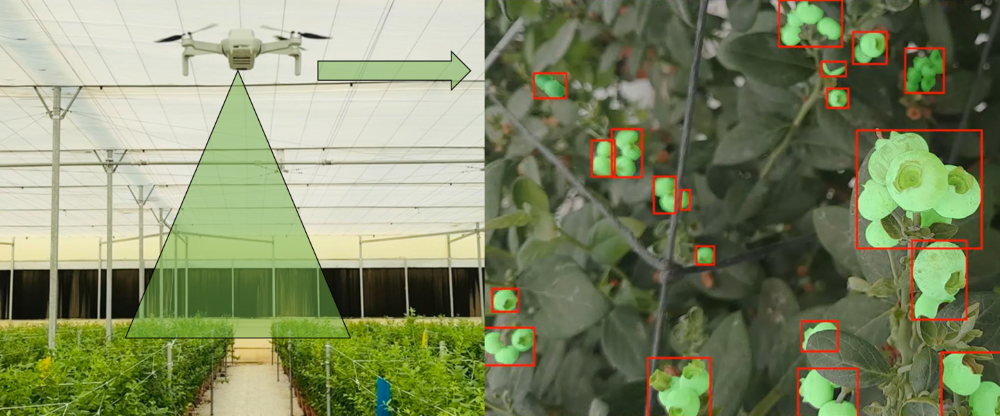

Imagine an AI-powered drone soaring over farmland, scanning fields to assess crop readiness. Below, a robotic pollinator mimics a bee’s dance with perfect precision, ensuring every plant is fertilized. As the fruits grow, a wearable smart device helps farmers check for perfect ripeness, while a smartphone app acts as an early warning system, instantly detecting diseases before they can spread.

This isn’t science fiction. It’s happening now in the United Arab Emirates, where researchers are building the world’s first fully autonomous, robotic greenhouse, designed to test whether robots can entirely replace human intervention in food production.

The UAE imports approximately 80% of its food1, making it one of the world’s most food-import-dependent nations. But at Khalifa University’s Center for Autonomous Robot Systems (KUCARS), a team of researchers is working to flip that narrative.

“We are living at the forefront of climate change challenges.”

Shamal Mohammed

Backed by Silal, a leading food hub in the UAE, the team is developing technologies that could revolutionize farming in extreme environments and potentially reshape the country’s food production.

The Center of Excellence in Agri Robotics and Automation, which represents a joint investment of approximately 15 million dirhams between Khalifa University and Silal, serves as a proof-of-concept for technologies that address challenges extending far beyond the UAE’s borders as climate change makes extreme farming conditions more common globally.

“We are living in the forefront of climate change challenges. Our soil is terrible. There is no fresh water, there is no rain. There are 165 days of sunshine, and the temperature right now is probably 45 °C,” says Shamal Mohammed, Head of AgriTech at Silal. “But we are not only developing solutions for our own food production, our innovation is going to be relevant to the rest of the world in the next decades.”

The 2,000m2 greenhouse will include real-world farming setups and a digital twin. This virtual environment mirrors the physical greenhouse in real-time, allowing researchers to test scenarios and optimize operations without disrupting actual crop production.

Irfan Hussain, associate professor at Khalifa University and agri-robotics team lead at KUCARS, and four specialized researchers are developing cutting-edge technologies to automate how crops are pollinated, monitored, and harvested. “We are building a facility that can provide a semi-realistic controlled environment during the process of translating our technologies from our KU agri-robotics lab to commercial greenhouses,” he says.

Overcoming the GPS challenge

One of the biggest challenges Hussain’s team faces is teaching robots to navigate without GPS. Traditional outdoor farming robots rely on GPS for positioning, but greenhouse indoor environments can block or weaken satellite signals.2 Hussain’s team has developed alternative methods that use cameras and sensors to help robots see and navigate, much like a person would.

“In underwater robotics, there is also no GPS,” Hussain notes. Various techniques can be used to tell robots where they are in a lab, where there are no crops, no obstacles, he explains. But it is more difficult in a commercial greenhouse.

The team uses motion-capture systems to test these localization techniques first in the lab and then again in the visually rich environment of a real greenhouse, with crops, plants and obstacles.

Four technologies to change farming

Beyond the autonomous greenhouse, the KU-Silal partnership has yielded four specific technologies that are being developed for commercial use. Silal has committed four million dirhams to bring these innovations from lab prototypes to market-ready solutions. These include a robot that pollinates every plant with precision, a smart thumb device that accurately checks fruit ripeness, an AI-powered drone which monitors fields, and a phone app that can instantly detect plant diseases.

This robotic revolution goes beyond mere automation. Team member Rajmeet Bhourji’s pollination technology represents a complete reimagining of how pollination works. “The bee might skip flowers,” he explains, but when a robot pollinates, “it scans the whole plant, identifies where the flowers are, goes there and does the pollination.” This is a fundamental improvement over biological pollinators. The robots work continuously with superior performance and precision.

“After COVID, you saw every country having to depend on other countries for food security.”

Rajmeet Bhourji

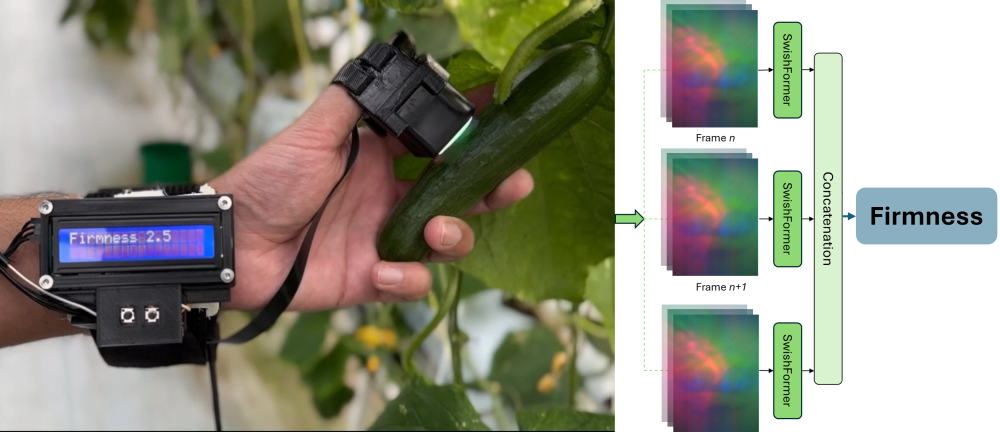

The choice of target crops for testing is also strategic. “If we start with blueberries and later move to tomato or capsicum, it will take only 10-20% of the development effort for other crops. But if we start with tomatoes and customize that technology for blueberries, it’s very challenging,” says research associate Mashood Mohsan, who has developed a wearable thumb device that measures fruit ripeness without harming produce.

Meanwhile, Muhammad Owais, a postdoctoral researcher on the team, is developing an AI-powered smart agri-tech drone that fuses computer vision and agricultural expertise for similar purposes. The fourth startup centers around a smartphone application that provides real-time plant disease detection.

From lab to market

Industry leaders and government officials are already showing interest—drawn by the potential to cut labor costs and solve harvesting bottlenecks.

The team follows a systems-thinking approach that allows them to rapidly adapt technologies across disciplines—for example, techniques for underwater navigation now inform greenhouse robot localization.

The timing of KU’s work proves particularly relevant as global food security concerns intensify. “After COVID, you saw every country having to depend on other countries for food security,” Bhourji notes. “But after implementing robot-based solutions in greenhouses and vertical farming, everyone can easily grow their own food and sustain their own population.”

Silal’s Mohammed believes this allows UAE researchers to develop solutions for conditions other regions will face in the coming decades. The protected environment in agriculture that’s necessary in the UAE today may become standard practice worldwide as temperatures rise and weather patterns become more unpredictable. “Some of these solutions might be relevant to local farms right now, but they might have a much bigger market somewhere else,” he explains.

Owais envisions rapid expansion across crop types while Mohsan sees global market potential for standardized fruit assessment. “Our goal is to export the technology. The first step will be to develop and deploy it in local farms, and the next step will be to start exporting once we go for commercialization.”

Bhourji also emphasizes the broader implications for food security and international development. “We want to reduce technology costs so everyone can easily afford it; not only Western or European countries, but for every farmer around the world.”

Challenges and the human touch

Despite promising developments, challenges remain. “Our AI-based method is still far from human accuracy, but we want to make it more accurate,” Owais says.

The improvement process relies heavily on data collection and iterative training. “AI-based methods are data dependent. If we can get more accurate, more diverse data for any particular field or crop, then we can train our AI model to improve its accuracy,” Owais explains. “This process involves collecting images and videos from real fields that capture different weather conditions and different ripeness levels, and all the other complexities that actually exist in real fields.”

Partnerships with companies such as Silal are important because they provide real-world validation, according to Mohsan. “With Silal, we plan to test under diverse conditions to ensure reliability, allowing both the product and the AI to mature. Our goal is to launch commercial products by next year, validated through trials with local farmers.”

Despite the focus on autonomous systems, Hussein and his team believe human expertise remains crucial to robotics application. Their robots and AI systems are designed to augment and enhance human capabilities rather than simply replace workers.

“When you work with end users, you understand what the requirements of the system are, how it will actually work. There’s a lot of iterative process, but you come up with solutions that work,” says Hussein.

References

- Huang, Z., Shiigi, T., Tsay, L., Nakanishi, H., Suzuki, T., Ogawa, Y. and Naoshi, K. A sound-based positioning system with centimeter accuracy for mobile robots in a greenhouse using frequency shift compensation. Computers and Electronics in Agriculture, 187, 2021