Pushing the boundaries of water technologies

At Khalifa University’s Centre for Membranes and Advanced Water Technology researchers are developing resilient, energy-efficient and cost-effective solutions to tackle water scarcity.

In the arid landscapes of the United Arab Emirates, the challenge of securing a clean and sustainable water supply is a pressing concern. The Centre for Membranes and Advanced Water Technology (CMAT) at Khalifa University Established in 2018, CMAT is a dynamic hub of innovation, focusing on advanced research to tackle water scarcity through cutting-edge technology.

Looking ahead at sustainable water solutions

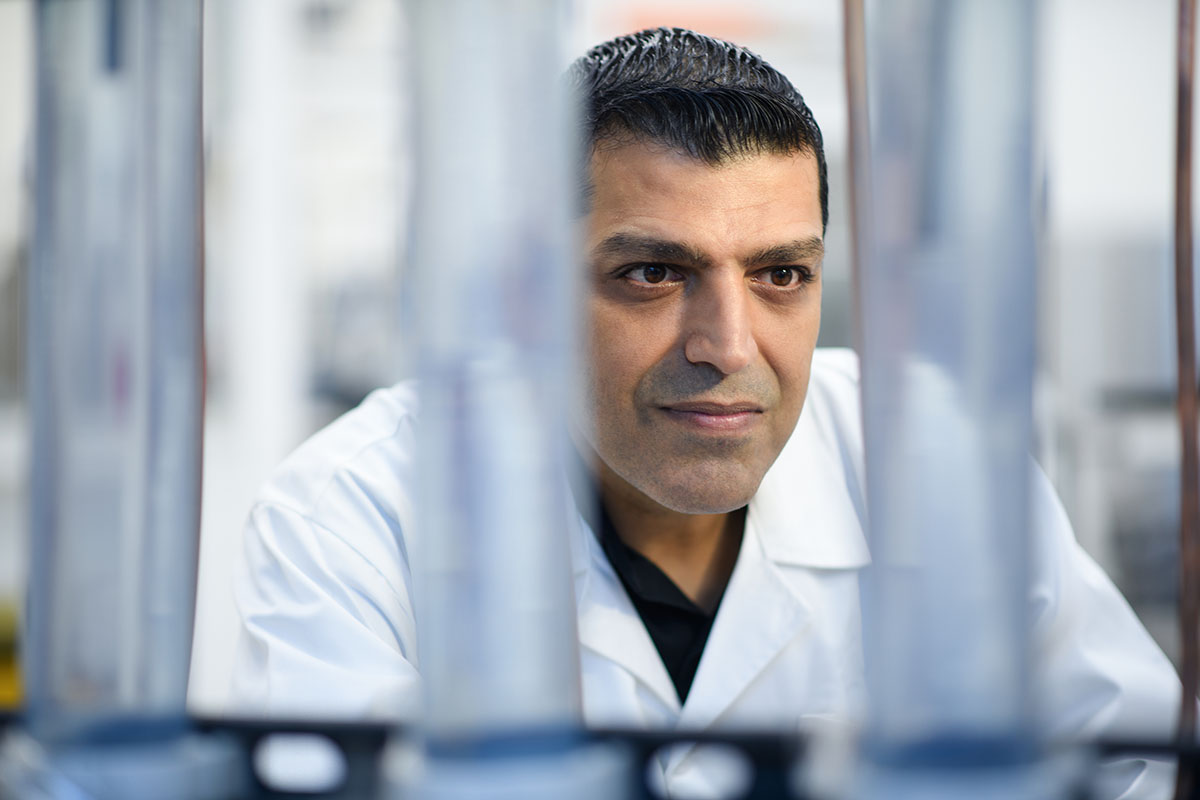

Aligning with Khalifa University’s overarching goal of advancing knowledge and fostering sustainable development, “CMAT’s mission is to pioneer innovative membrane and water technologies that address pressing water-scarcity challenges,” explains center director Shadi Hasan, an associate professor in the Department of Chemical and Petroleum Engineering.

The drive behind establishing CMAT was the urgent need for integrated water management solutions to be resilient, energy efficient, environmentally friendly, and cost effective. “We face growing water-scarcity challenges that require long-term sustainable solutions,” Hasan says. “CMAT fosters innovation and technology transfer to relevant stakeholders, aiming to become a global leader in the field.”

“CMAT’s mission is to pioneer innovative membrane and water technologies that address pressing water scarcity challenges.”

Shadi Hasan

The center’s research portfolio is extensive, with numerous projects breaking new ground in water technology. One of these involves integrating 2D materials, such as graphene, into membrane technology for desalination pretreatment, aiming to reduce the overall energy consumption of the seawater desalination process.

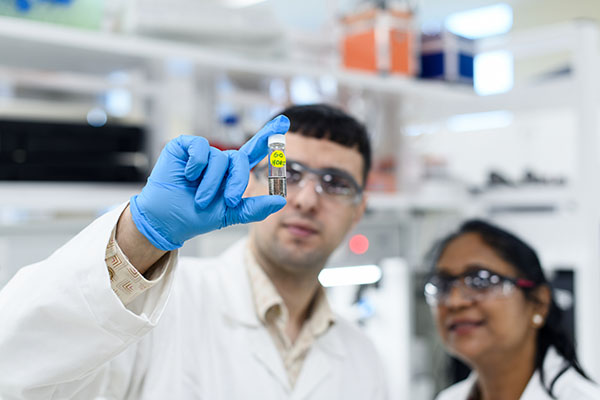

CMAT’s PhD students and research staff are also developing advanced membranes capable of removing a wide range of contaminants, including polyfluoroalkyl substances, microplastics, and pharmaceuticals.

Mariam Ouda, a third-year PhD student, is developing an electro-membrane filtration system using emerging 2D materials known as MXenes. “We apply electricity to the membrane to induce various electrochemical processes,” explains Ouda, whose research targets micro and nanoplastic pollutants, which are emerging challenges in water treatment.

“These membranes showed promising results in mitigating microplastic fouling while maintaining water flux. By applying electrical potentials, the membranes demonstrated improved performance,” Ouda says. “Additionally, intermittent voltage application showed enhanced stability in water flux, offering a potential solution for long-term membrane operation.”

Harnessing solar energy

Jehad Kharraz, a postdoctoral fellow at CMAT, is working with a team of researchers including Hanaa Hegab and two PhD students, Lobna Nassar and Ahmad Jawed, on an innovative project using solar energy in photothermal membrane distillation. “This is a cutting-edge water desalination technique that harnesses solar energy to drive the distillation process,” Kharraz explains. “In this method, solar energy is absorbed by a photothermal material, which then generates heat used to evaporate water. The vapor is then condensed on a membrane surface, resulting in purified water.”

“By using materials that respond to environmental conditions, we can improve the efficiency and adaptability of wastewater treatment processes.”

Fatima Khamis

This innovative approach offers a sustainable and energy-efficient solution to produce fresh water from seawater or brackish water sources, with the potential to address water-scarcity challenges in arid regions. Traditional technologies such as reverse osmosis are limited in their ability to treat highly saline water, for example reject brine, but membrane distillation can overcome this limitation. “Our process reduces the energy required for desalination,” Kharraz says. “It aligns with our goal of developing energy-efficient water treatment processes, which is crucial for regions such as the UAE where energy resources are precious.”

Developing eco-friendly membranes

Fatima Khamis, a third-year PhD student, is at the forefront of developing innovative and eco-friendly pH-responsive absorptive membranes for wastewater treatment. Her research focuses on integrating materials from mangroves into eco-friendly biopolymers that can effectively remove microplastics and heavy metals from wastewater.

“Our membranes can change properties in response to pH variations, enhancing the absorption and removal of these pollutants,” Khamis says.

This innovative approach targets microplastics and heavy metals in a more sustainable water treatment solution. “By using materials that respond to environmental conditions, we can improve the efficiency and adaptability of wastewater treatment processes,” Khamis adds.

“By using materials that respond to environmental conditions, we can improve the efficiency and adaptability of wastewater treatment processes.”

Fatima Khamis

With a strong commitment to sustainability, this research contributes to the broader goal of developing environmentally friendly technologies that minimize the impact of pollutants on ecosystems.

Resource recovery from brine

Resource recovery from brine is another significant focus area for CMAT researchers. “Recovering valuable resources such as lithium, calcium and magnesium from brine is becoming a pivotal research area,” Hasan says.

“Currently, brine is treated as waste, but we aim to recover valuable resources such as magnesium and lithium… This research fits into the circular economy concept.”

Faisal AlMarzooqi

Faisal AlMarzooqi, an associate professor and deputy director of CMAT, explains that brine is curently treated as waste. “We aim to recover valuable resources such as magnesium and lithium. Magnesium is widely used in construction and electronics, while lithium is crucial for lithium-ion batteries,” he says.

“This research fits into the circular economy concept,” AlMarzooqi adds. “By recovering and reusing these elements, we can make our processes more sustainable and economically viable.”

Going green

Professor of chemical and petroleum engineeringEnas Nashef’s research emphasizes the replacement of harmful commercial solvents. “Most commercial solvents are volatile, toxic, and non-biodegradable,” Nashef says. “We aim to replace these with green solvents including ionic liquids and deep eutectic solvents, which are non-volatile, biodegradable, and have low toxicity.”

These green solvents are being used for various applications, including fuel purification, carbon dioxide capture, and wastewater treatment. “We have achieved great results and even filed a patent for a novel method using green solvents for water purification,” Nashef reveals.

Sana Eid, a fourth-year PhD student, is tackling the challenge of removing persistent emerging pollutants known as perfluoroalkyl and polyfluoroalkyl substances (PFAS) using green solvents.

“PFAS are notoriously difficult to remove from water due to their chemical stability and persistence,” says Eid. “Our research focuses on using deep eutectic solvents, which are environmentally benign, to extract these pollutants from water sources effectively.”

“CMAT fosters innovation and technology transfer to relevant stakeholders, aiming to become a global leader in the field.”

Shadi Hasan

Deep eutectic solvents offer a promising solution due to their unique properties including low volatility, biodegradability and the ability to dissolve a wide range of substances. “By incorporating these solvents into membrane technology, we can enhance the removal efficiency of PFAS and other persistent pollutants,” Eid explains. This research is crucial as it addresses the challenge of emerging contaminants that traditional water-treatment methods struggle to eliminate.

Fostering innovation

CMAT’s success is underpinned by its collaborative environment, bringing together researchers, students, and industry partners. “We have over 100 people using our research facilities,” Hasan says. “Our six well-established laboratories cover various specialized areas, from material synthesis to membrane fabrication, characterization and testing.”

The center’s commitment to fostering innovation is evident in its engagement with both national and international scholars and industries. “We are discussing potential projects with industry and governmental entities to take our pilot plants into the field for further research,” Hasan adds. This collaborative approach ensures that CMAT’s research not only advances scientific knowledge but also translates into practical solutions for water sustainability.

As CMAT research teams continue to push the boundaries of water technology, they remain focused on addressing the critical challenges of water scarcity and environmental sustainability. “Our vision is to become a global leader in the field, driving impactful solutions for water sustainability while nurturing a culture of excellence and collaboration,” Hasan says.