Printing materials by design

Rashid K. Abu Al-Rub, Professor of Mechanical Engineering at Khalifa University

Rashid K. Abu Al-Rub has always been fascinated by nature’s intricate engineering of the microstructure of materials to give them function. A structural engineer by training, the Lead of Advanced Digital & Additive Manufacturing (ADAM) Group at Khalifa University channels this fascination into his research, combining insights from the architectural design of large structural systems, such as buildings and bridges, and nature to innovate in materials science.

What has been the focus of your work in the past few years?

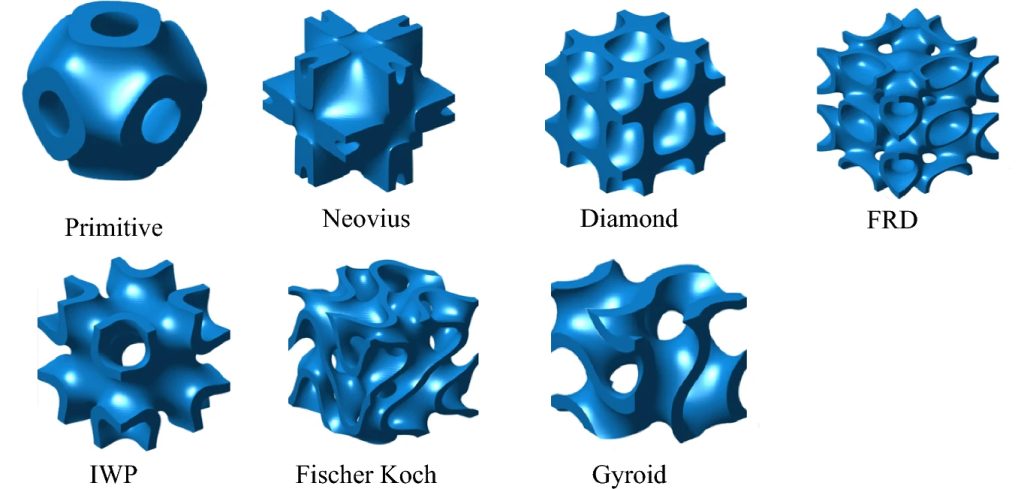

My research has centered on engineered metamaterials, a unique class of engineered materials distinguished by their tailored architectural design at the macro, micro, or nano scale. Specifically, I explore the multifunctional properties of a special class of metamaterials known as triply periodic minimal surfaces (TPMS). These are surfaces that repeat themselves periodically in three-dimensional space and have smooth, intricate and intertwined topological features.

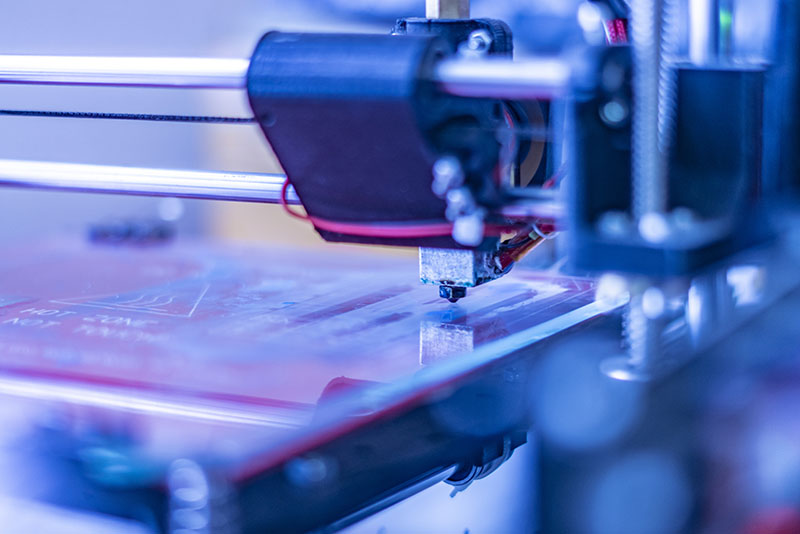

While TPMS have been well-known to mathematicians for more than 160 years, their complicated design posed fabrication challenges when using traditional manufacturing methods. However, recent advances in additive manufacturing and 3D printing have opened the door to metamaterials with very complicated microstructures. I consider myself lucky to have started working on TPMS metamaterials a decade ago, when the 3D-printing boom started. Today ADAM is at the forefront of TPMS-metamaterial research.

“Recent advances in digital-design software have removed a lot of the constraints that engineers faced when designing components for fabrication using conventional manufacturing methods.”

Rashid Abu Al-Rub

What are the potential applications of these engineered materials?

We have developed numerous types of TPMS metamaterials and characterized their mechanical and physical properties. We found that these materials hold promise across a spectrum of applications such as lightweight yet robust structures, catalytic substrates for carbon-dioxide capture and conversion, feed spacers and membranes in water technologies, acoustic and electromagnetic absorbers, heat exchangers, heat sinks, and energy storage. I can say with confidence that our research on TPMS metamaterials is not only gaining traction within academia and industry but also contributing to the global surge of interest in metamaterials.

What do you consider to be the most exciting advance in additive manufacturing?

Beyond the 3D printers themselves, the true excitement lies in digital-design software, without which, 3D printers are not functional. Recent advances there have liberated engineers from many of the constraints they faced with conventional manufacturing methods.

What breakthroughs do you anticipate in the next decade?

I see two possible breakthroughs. The first is the ability to quickly design a material’s architecture by simply specifying the desired properties and performance using digital-design tools, perhaps based on artificial intelligence. The second is the significant increase in the speed of manufacturing plastic and metal parts using 3D printers, We can reduce fabrication times from hours or days, today, to minutes. These two breakthroughs will definitely change the game.