Inventing contact lenses that correct color-blindness

Haider Butt, Professor of Mechanical and Nuclear Engineering, Khalifa University of Science and Technology

When and how did you join Khalifa University’s College of Engineering?

I join Khalifa University (KU) in 2019, initially as an Associate Professor in the Department of Mechanical Engineering. I was promoted to a Full Professor in July 2023. Before joining KU, I spend over 5 years at the University of Birmingham (UK) as a Senior Lecturer of Nanotechnology.

Please describe your research.

In broad terms, my research focuses on developing smart wearable devices for healthcare monitoring and diagnostics. I lead a research team of around 10 graduate students and post-doctoral researchers. One of our main focus areas is the development of economical contact lenses for tackling color blindness and related eye conditions. We produce tinted contact lenses using 3D printing techniques and materials and dyes developed in-house. The dye — a rhodamine derivative — filters out specific wavelength bands (545-575 nm) to correct color blindness[1] . Our group is internationally known for this pioneering work on 3D printed tinted contact lenses, and we regularly interact with patients and clinicians.

Why were you drawn to mechanical engineering and nanotechnology?

For as long as I can remember, I have been a very visual person and I am naturally attracted to colorful materials and organisms, such as butterflies. As is widely known, the color of butterflies originates not from dyes or chemicals but rather from tiny nanostructures found in their wings. Nanostructures have comparable dimensions to the wavelength of light, which makes them exhibit fascinating, bright colors. This link between nanotechnology and light, also known as Nanophotonics, is my key interest in this field, and hence it is also in the name of our research group, Nanophotonics Group. It is no surprise that almost all of our inventions are colorful, including the pink-colored contact lenses that tackle color blindness.

What tech do you use?

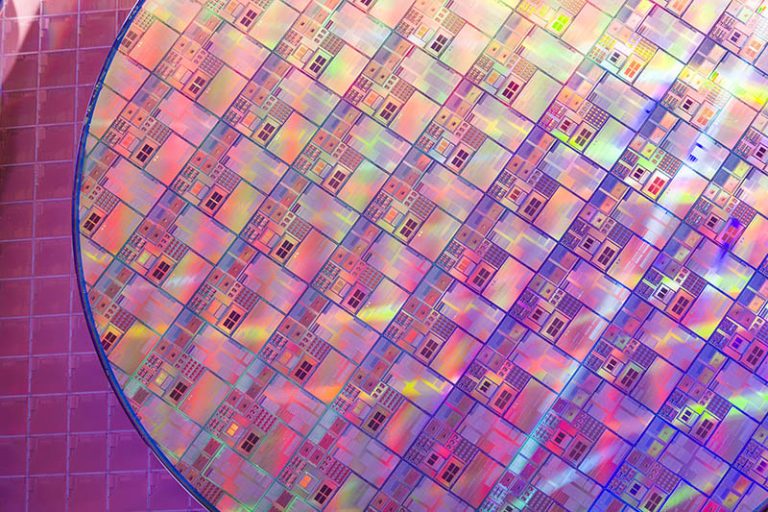

In my research group our focus is always to produce nanomaterials through economical means, so we use laser- and chemistry-based processes. In addition to that, for the production of contact lenses we use open-source 3D printers.

What excites you about your work?

It excites and motivates me to think that one day our inventions (including the tinted contact lenses) can be commercialized and will potentially help millions of color-blind patients improve their vision and quality of life. Beyond those real-world impacts of our research, I also enjoy interacting with my graduate students. And seeing them build their research careers gives me great contentment.

What work are you most proud of?

That would have to be our pioneering work on contact lenses for color blind patients (link). The work was highlighted in global news media and it brought us a lot of attention from the industry and clinicians. More importantly, the work allowed me to interact with the color-blind patients and to learn directly from them about their life-long struggles. The longing of patients for such products is a source of motivation for us.

What is the most exciting recent discovery in your field, in your view?

We have recently developed a technique to 3D print multi-material contact lenses (link). In my view this is a big milestone in the field, as traditionally contact lenses are only produced with singular materials. With this new process we can incorporate a number of functional materials into a single contact lens and make it into an intelligent wearable device that can sense analytes, correct vision, filter colors and also react to changing environments.

What has been your most memorable experience at Khalifa University?

I’ve thoroughly enjoyed interacting and training my undergraduate and graduate students. And of course my promotion to a Full Professor at Khalifa University will always remain a memorable experience.

Haider Butt

ProfessorMechanical Engineering

Advanced Digital & Additive Manufacturing Center

haider.butt@ku.ac.ae